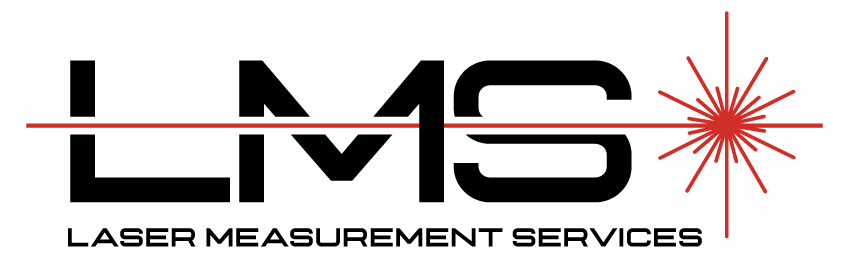

Linear Calibration

LMS uses Renishaw XL-80 laser interferometers for linear, straightness, squareness, pitch and yaw analysis. The XL-80 can measure up to 80 meters in length with an accuracy of +/- 0.5 ppm and it offers resolution down to a nanometer.

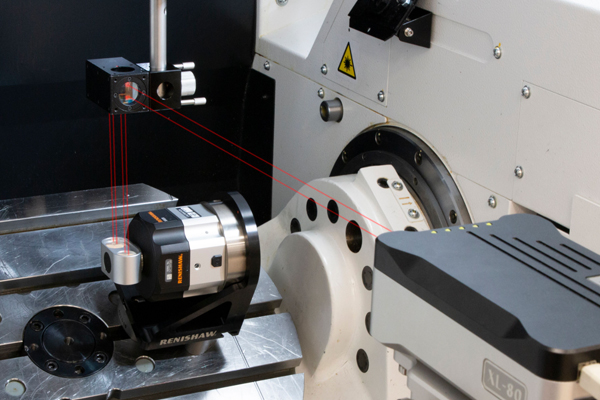

Rotary Axis Calibration

LMS uses Renishaw XR20-W Rotary Axis calibrator for rotary axis calibration. The XR20-W system allows us to measure rotational axis position to within 1 arc second.

Dynamic Ballbar Testing

LMS uses the Renishaw QC20-W wireless ballbar system for dynamic machine tool performance diagnosis. The ballbar has a system accuracy of +/- 1.25µm and can be set to calibration from 100 to 600mm radius. Tests are performed in both clockwise and counterclockwise directions to evaluate error.

Laser Leveling & Alignment Services

LMS uses Hamar Laser’s L-743 Ultra-Precision Triple Scan Laser Alignment System that is the most accurate and versatile alignment tool on the market today. This powerful system is ideal for quickly and accurately checking and fixing the geometry of almost all CNC machining centers and milling machines, as well as many other demanding applications. The Precision Series L-743 are the only alignment systems in the world to offer 3 automatically rotating laser planes with the extremely high accuracy needed for today’s ever-tightening tolerances.

Our Services

- Linear Positioning

- Angular Positioning

- Straightness

- Pitch

- Yaw

- Roll

- Alignments (Squareness/Geometries)

- Leveling

- Flatness

- Parrallelism

- Compensation Mapping (Linear, Straightness, Squareness, & Full Volumetric)

- Reversal Error Adjustments

- Servo Adjustments

We are an “On Site ” calibration service of all types of CNC machine tools

- Vertical Machining Centers

- Gantry Machines

- Bridge Machines

- Horizontal Boring Mills

- Lathes

- Deep Hole Drilling Machines (Gun Drill)

- Electrical Discharge Machines (EDM)

- Coordinate Measuring Machines (CMM)